close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-08 Origin: Site

Sandy soils often face liquefaction and settlement risks. Builders need reliable ways to improve their strength. Vibroflotation Equipment offers proven solutions. In this article, you'll discover the advantages of using top feed vibroflots for sandy soil projects.

Sandy soils drain water quickly but lack cohesion. Their loose particle structure makes them easy to compact but unstable under heavy loads. Unlike clay, they do not bind together, so they shift easily when exposed to pressure or vibration. This unstable nature creates challenges for long-term foundation stability.

One of the greatest risks in sandy soils is liquefaction. During earthquakes or high water pressure, particles lose contact, and the soil behaves like a liquid. This can lead to sudden settlement or even collapse of structures. Differential settlement is another concern, where some areas sink faster than others, causing cracks or uneven support. Sandy soils also have poor natural load-bearing capacity, which limits their use in construction without reinforcement.

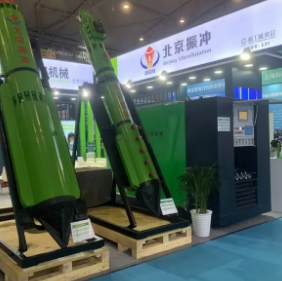

Contractors have used several methods to improve sandy soils. These include deep foundations, preloading, or soil replacement. While effective, these methods are often costly, slow, and disruptive. Vibroflotation Equipment provides a modern alternative. It uses high-frequency vibration to densify sandy soils, reducing settlement risks and boosting strength. The top feed method further enhances performance by filling voids with gravel or stone, ensuring long-term stability.

Method |

Pros |

Cons |

Soil Replacement |

Reliable improvement |

High cost, large excavation needed |

Preloading |

Reduces settlement risk |

Long time, heavy surcharge required |

Deep Foundations |

Handles heavy structures |

Expensive, complex installation |

Vibroflotation Equipment |

Fast, efficient, cost-effective |

Needs specialized equipment and skills |

Note: Choosing Vibroflotation Equipment reduces both cost and project delays compared to traditional soil replacement.

Top feed vibroflots rely on high-frequency vibration. The probe penetrates the soil and shakes loose particles. As grains shift, they move into a denser arrangement. This process raises shear strength and reduces void spaces. When applied in sandy soils, densification lowers the risk of sudden settlement and increases overall ground stability.

During operation, gravel or crushed stone is introduced from the surface. These materials fill spaces between soil grains, preventing re-loosening after compaction. The stone also enhances load transfer by acting as reinforcement columns. Combined with vibration, this dual action creates a stable soil matrix that can safely support structures.

In sandy soils, top feed is often more efficient than bottom feed. The top-down approach allows faster placement of gravel, especially when soil collapse is less of a risk. Bottom feed methods are preferred for saturated clays or silts, where stability is critical during probe withdrawal. For sandy sites, top feed vibroflots deliver faster cycles and require less water jetting, reducing complexity and cost.

Vibroflotation Equipment improves productivity by reducing the time needed for compaction cycles. Operators can adjust vibration duration and gravel feed rates to match soil conditions. Shorter cycle times mean larger areas can be treated in less time. This efficiency reduces labor and equipment costs, making it attractive for large-scale projects such as ports, reclamation sites, and industrial foundations.

The most direct benefit of using top feed vibroflots is the increase in soil density. Sandy particles rearrange under vibration, locking into a stronger structure. This densification raises shear strength, which is essential for supporting heavy loads. With Vibroflotation Equipment, engineers can achieve consistent density improvements across both shallow and deep layers.

Loose sandy soils are highly vulnerable during seismic events. When pore water pressure rises, the soil may lose its strength and behave like a liquid. Vibroflotation densifies the soil mass, reducing excess pressure buildup. This minimizes liquefaction risk, helping foundations remain stable in earthquake-prone areas. For projects in coastal or reclaimed lands, this benefit is especially valuable.

Time is critical in large infrastructure projects. Vibroflotation Equipment operates in repetitive cycles, each combining vibration and gravel feed. These cycles achieve rapid densification without requiring soil removal. By cutting down preparation and treatment time, contractors can shorten schedules significantly. Faster compaction means reduced labor costs and less disruption to surrounding areas.

Top feed vibroflots adapt well to varying soil depths. They can treat shallow sandy layers where simple compaction is enough, and they also reach deeper zones when heavy foundations require stronger support. The ability to adjust vibration intensity and feed rates gives project managers control over performance outcomes. This flexibility makes Vibroflotation Equipment suitable for a wide range of sandy soil projects, from small commercial sites to large marine works.

Deep piling and soil replacement methods deliver stability, but at high financial and environmental costs. Vibroflotation requires less excavation and generates minimal waste. This reduces material handling, transport, and disposal expenses. For mid- to large-scale projects, savings can be substantial while still achieving reliable soil improvement. Compared to traditional piling, vibroflotation often requires smaller foundations, lowering concrete and reinforcement costs.

Settlement can weaken structures over time. Vibroflotation Equipment reduces voids and improves uniformity in sandy soils. This leads to better load distribution and less differential settlement. Over decades, treated ground remains more durable, protecting buildings, bridges, and industrial facilities from costly repairs. Engineers value this long-term stability, especially for projects where maintenance access is limited.

Sustainability is increasingly important in construction. Vibroflotation produces very little spoil since soil is compacted in place. It also allows the use of recycled gravel or aggregates for filling, lowering resource demand. By reducing concrete use compared to piling, it decreases carbon emissions. For developers aiming to meet green building targets, vibroflotation offers both environmental and economic benefits.

Advantage |

Practical Benefit |

Higher soil density & shear strength |

Stronger foundations with improved load support |

Reduced liquefaction risk |

Safer performance in seismic zones |

Faster compaction cycles |

Shorter project schedules, lower labor costs |

Flexible application depth |

Suitable for shallow and deep sandy layers |

Cost-effective method |

Lower expenses vs. piling or soil replacement |

Settlement control |

Increased durability and service life |

Sustainability benefits |

Less spoil, lower carbon footprint |

Foundations depend on strong soil to resist loads. Vibroflotation Equipment improves this by densifying sandy layers and filling voids with gravel. The result is soil that behaves more like a stable mass, reducing the risk of shear failure. Stronger soil translates into safer and more reliable support for heavy structures.

Shallow foundations, such as slabs and spread footings, often suffer from uneven settlement in sandy ground. Vibroflotation reduces this by creating denser soil just below the base. For deep foundations, it increases lateral support, making piles or piers more effective. Both shallow and deep designs benefit from reduced settlement, better load distribution, and long-term durability.

Buildings on sandy sites gain better performance after vibroflotation. Residential and commercial structures avoid long-term settlement issues. Ports and harbor facilities often rely on vibroflotation to stabilize reclaimed sandy land, making docks and cranes safer. Large reclamation projects also use this method to transform weak seabed soils into usable construction platforms.

Sandy soils are vulnerable during seismic events. Excess pore water pressure can cause them to lose strength. Vibroflotation Equipment reduces this risk by densifying the soil and creating stone columns that drain water quickly. As a result, ground treated with top feed vibroflots is more stable, allowing buildings and infrastructure to withstand shaking with less damage.

Structural failures often occur when foundations lose uniform support. By improving shear strength and reducing settlement, vibroflotation creates a safer base for heavy loads. Engineers use this method to protect roads, ports, and tall structures built on sandy sites. The improved soil matrix prevents sudden ground shifts that can lead to cracks or collapse.

Safety depends not only on the method but also on execution. Modern Vibroflotation Equipment is often paired with monitoring tools such as data loggers. These track depth, compaction rate, and gravel volume during each cycle. Continuous monitoring ensures that soil treatment meets design standards and provides reliable performance over the long term.

Time and labor are two of the largest expenses in ground improvement projects. Top feed vibroflots reduce both by streamlining the soil densification process. Unlike soil replacement or piling, which require extensive excavation and support equipment, Vibroflotation Equipment completes cycles quickly with fewer operators. Each cycle compacts soil and fills voids in a single operation, minimizing idle time between steps. For contractors, this translates into lower man-hours per square meter of treated soil.

Operators can also control vibration intensity and gravel feed rate to match site conditions. These adjustments increase precision and reduce wasted effort. On large sandy areas, a fleet of vibroflots can work simultaneously, achieving consistent compaction while keeping crews small. By lowering labor requirements, projects maintain quality while reducing overhead.

When comparing methods, vibroflotation often stands out as more economical. Piling demands specialized rigs, heavy reinforcement, and large volumes of concrete. Soil replacement requires excavation, trucking, and disposal of spoil, all of which raise costs. Preloading adds weeks or months of waiting for soils to settle.

Vibroflotation avoids these issues by treating soil in place. It requires less material, less transport, and less energy. Because the process is non-disruptive, it also reduces costs linked to site disturbance, such as road closures or additional safety measures. For sandy soils, where densification is the main goal, vibroflotation achieves equivalent or superior results at a fraction of the cost.

Reclaiming land from the sea or riverbanks often involves sandy deposits that are weak and unstable. Vibroflotation Equipment compacts these soils and forms gravel columns that strengthen the reclaimed ground. This ensures the new land can safely support heavy loads. Countries expanding coastal cities or creating artificial islands rely on this method because it improves both stability and resilience to water pressure.

Marine construction depends on strong ground to hold cranes, warehouses, and shipping infrastructure. Sandy seabeds pose challenges due to low density and high liquefaction risk. Vibroflotation densifies these soils, reducing movement under waves or ship loads. It also helps anchor quay walls and breakwaters. By stabilizing large areas quickly, contractors keep projects on schedule and minimize marine disruption.

Factories, warehouses, and high-traffic commercial facilities often rise on sandy plains. Without ground improvement, foundations would face settlement or cracking. Vibroflotation Equipment creates a stable base by improving shear strength and uniformity. This allows builders to use shallow foundations rather than costly piling. For developers, this means reduced construction costs and long-term reliability of industrial floors and heavy machinery platforms.

Roads, railways, and airport runways on sandy soils need strong subgrades to carry dynamic loads. Vibroflotation compacts the soil below pavements, limiting rutting and uneven settlement. Runways benefit in particular because planes exert high concentrated loads during landing and takeoff. With vibroflotation, the soil remains firm, supporting safe operations and reducing repair cycles.

Top feed vibroflots solve sandy soil problems by improving density and reducing settlement. They deliver strong, safe, and efficient ground improvement with clear cost benefits. For decision-makers, Vibroflotation Equipment is a proven choice for sandy soil projects. BVEM offers advanced solutions that enhance performance and ensure long-term stability. Their products provide reliable value for construction and infrastructure development worldwide.

A: They increase soil density, improve stability, and reduce settlement risks.

A: Vibroflotation Equipment densifies soil through vibration and fills voids with gravel.

A: It is faster, more cost-effective, and minimizes excavation waste.

A: Yes, it is widely applied in land reclamation, harbors, and infrastructure works.